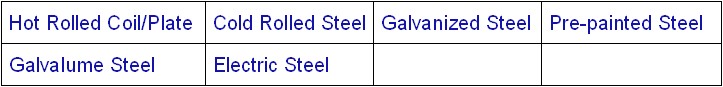

1.Hot Rolled Sheet/Plate

Product Description:

Hot rolling is metalworking process that occurs above the recrystallization temperature of the material. It is used mainly to produce sheet metal or simple cross sections, such as rail tracks.

Features:

High intensity, good tenacity, easy for mould-processing and good for welding, used as raw material of cold rolled and coated products, also directly in welding pipes and tubes, shipbuilding, construction, automobile, pressure vessels, etc

| Main Specifications | Thickness from 8-150mm, width from 1400-4000mm, length from 6000-28000mm. hot rolled coil :1.8-25mm *1250-2020mm*L | |

|---|---|---|

| Standard and Grade | Chinese Standard | Q235A,Q235B,Q345A,Q345B,ST52-3,Q235C,,Q235D,Q345D,Q345E,Q345E-1,Q390A,Q390B,Q390C,Q390D,Q390E,Q420C,Q420D,Q420E, Q460C,Q460D,Q500D,Q550D,SQ550D,16Mnq,Q345qC,Q345qD, Q345qE,Q370qC,Q370qD,Q370qE,Q420qC,Q420qD,Q420qE, 10#,15#, 20#, 30-45#, 50#,20Mn, Q345GJC, Q345GJD, Q245R, Q345R, 16MnDR,Q370R,16MnL |

| Japanese Standard | SS400 ,SM400A,SM400B, SM490A,SM490B,SM520B,SM520C | |

| European Standard | S235JR, S235J0,S235J2,S275JR,S275J0, S275J2,S355JR,S355JO,S355J2, S355J2G3, S355K2, S355N | |

| American Standard | A283 Gr.A,A283 Gr.B, A283 Gr.C, A283 Gr.D,A285 Gr.A, A285 Gr.B, A285 Gr.C,A572-GR50,SA515/516/GR55, SA515/516/GR60, SA515/516/GR65, SA515/516/GR70, A573 Gr.58,A709 Gr.36, A709 Gr.50; A537 CL1,A537 CL2, A537 CL3, A387 GR.11CL2, A633 Gr D, A36 | |

| Shipbuilding Steel | A, B, D, AH32, DH32, AH36, DH36,EH32, EH36,AH40/DH40/EH40 | |

| Pipe Line | L210, L245, X42 X46, X52, X56, X60, X65, X70, X80 | |

| Alloy Boiler Container Board | 15CrMoR, 12Cr1MoVR, 07MnCrMoVR, 07MnNiMoVDR, 09MnNiDR, 13MnNiMoR, 14Cr1MoR | |

| Tank Plate | SG610D/E | |

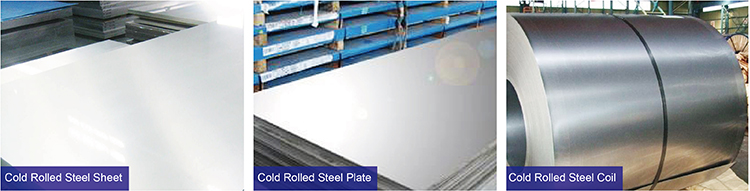

2.Cold Rolled Steel

1、Hot rolled acid pickled:

Pickling is treatment of metallic surfaces to remove impurities, stains, rust or scale with a solution called pickling liquor, containing strong mineral acids, before subsequent processing, such as extrusion, rolling, painting, galvanizing or plating with zinc,aluminum,etc..

Features: 1. Good surface; 2. High precision

Standard:

| Pickled | ||||

| GBT699/GBT700 | JIS G 3131-96 | ASTM/SAEJ403 | EN10111 | |

| CQ | Q195 10 08 |

SPHC | A569M SAE1008 |

DD11 |

| DQ | 08 08A1 |

SPHD | A621M SAE1006 |

DD12 |

| DDQ | Q215B/Q235B/Q275 | --- | --- | --- |

2、Rolled hard steel coil:Roll the hot rolled acid pickled steel coil under usual temperature.

Features of parts:As this kind of steel hasn’t been annealed ,the hardness is pretty high and difficult to proceed mechanic processing. Only the deformation less than 90 degree is practical (vertical to coiling direction).

Application Scale :

(1)Processed into common cold rolled steel after annealing

(2)Zinc galvanizing is conducted prior to annealing.

(3)Steel plate which doesn’t need any processing .

Frequently used designation

CDCM - SPCC (SPCD、SPCE、ST12、ST13、ST14、BLC、BLD、BUSD、BUFD、 BSUFD等),

CDCM - SPCC (SPCD、SPCE、ST12、ST13、ST14、BLC、BLD、BUSD、BUFD、BSUFD and so on.Steel of those designation share similar properties.

3.GALVANISED STEEL

After degreasing treatment of steel strip made from cold rolling machine line ,steel strip is sent to continuous hot zinc galvanized machine line for the following processing:

1. annealed in annealing furnace.

2. hot dipped and zinc galvanized in molten zinc .

3. passivation or polishing

4. elongation and leveling

All the processing above constitute necessary manufacturing steps of hot zinc galvanized steel plate.

Hot zinc galvanized steel plate increasingly applies to apparatus, automotive , machines in office ,furniture and architecture.

| Classification | Catalogue | Product | Characteristics | Usage |

|---|---|---|---|---|

| Properties of steel plate | Hot rolled steel plate | Hot rolled hot zinc galvanized steel plate | SiIngle piece | Industry, civil construction |

| Common cold rolled steel plate | Cold rolled hot zinc galvanized steel plate | Coil and shearing | Industry, civil construction | |

| IF steel plate | IF hot zinc galvanized steel plate | Drawing will bring better property. | Automotive industry | |

| Surface and appearance | Large spangle | Large spangle zinc galvanized steel plate | Large and beautiful spangle | Industry, civil construction |

| Small spangle | Small spangle zinc galvanized steel plate | Small and evenly distributed spangle | Automotive and light industry | |

| Zero spangle | Spangle zinc galvanized steel plate | Zero spangle | Automotive and light industry | |

| Ingredient of zinc layer | Little Pb,Al contained | Spangle hot zinc galvanized steel plate | With spangle | Industry and civil construction |

| No Pb | Zero spangle zinc galvanized steel plate | Zero spangle ,corrosion resistant | Apparatus, automotive industry | |

| Fe-Zn alloy | Zinc alloy coated steel plate | Not shining , easily coated and welded | Automotive and light industry | |

| Zn-5%Al | Glfan steel plate | Atmospheric corrosion resistant | Industry and civil construction | |

| Zn-55%Al | Galvalum steel plate | Atmospheric corrosion resistant and oxidization resistant when temperature below 400 ℃ | Civil construction ,food industry and light industry | |

| Surface structure | Double side zinc galvanized | Zinc galvanized steel plate | Double side zinc galvanized, different material of zinc layer leads to different catalogue | Civil construction and light industry |

| Zinc layer of different thickness | Double side zinc galvanized, and zinc layers are of different thickness | Automotive industry |

4.PRE-PAINTED STEEL

In the continuous processing machine, cold rolled steel sheet and zinc galvanized steel sheet served as basal plate, one layer or several layers of liquid paint are painted onto the basal plate after surface pretreatment. Steel sheet is changed into coated steel sheet after baking and cooling. As the layer bears different colors, thus coated steel sheet is also known as color coated steel sheet. Besides, because painting is preceded prior to the formation processing, coated steel sheet is also called as pre-coated steel sheet. .In this processing ,traditionally adopted spraying is replaced by continuous painting, which is conducive to surface treatment ,quality control of coating layer and avoid defects in edges.

(1) Application of color coated steel sheet

>> Application of color coated steel sheet:

Outdoor: roof, roof structure, surface sheet of balcony, frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, refrigerated wagon and so on.

Indoor: door, isolater, frame of door, light steel structure of house, sliding door, folding screen, ceiling, internal decoration of toilet and elevator.

>> Application in apparatus

Refrigerator, refrigerated wagon, washing machine, electric baker, automatic selling machine, air conditioner, copying machine, cabinet, electric fan, vacuum sweeper and so on.

>> Application in transportation

Ceiling of automobile, board , internal decoration board, external shelf of automobile, carriage board, car ,instrument panel, shelf of operating platform, trolley bus, ceiling of railway, color isolator of ship, furniture of ship, floor, cargo container and so on.

>> Application in furniture and sheet metal processing

Electric warming oven, shelf of water heater, counter, shelves, chest of drawers ,chair,

archive cabinet, book shelves.

5.Galvalume Steel

Product Description:

Galvolume/Galfan products (GL) use cold rolled steel sheets with various strengths and thicknesses as the raw materials and are coated with aluminum (Al 55%), zinc (Zn 43.5%) and silicon (Si 1.5%) alloy. It possesses excellent anti-corrosion properties.

Product Features:

Derived from hot-dip aluminum galvanization and hot-dip zinc galvanization technology, Galvolume/Galfan products possess excellent properties of both products, i.e. the exceptional anti-corrosion and anti-oxidation properties of hot-dip aluminum galvanization, and superior electric-chemical properties of hot-dip zinc galvanization, which make Galvolume/Galfan sheets less prone to rust and corrosion at the edge and on the scratched surface. The major properties of Galvolume/Galfan steel sheets include the following:

(1) Smooth surface and superior anti-corrosion property. They can resist corrosion up to 2 to 6 times longer than hot-dip zinc galvanized steel sheets;

(2) Excellent heat resistance and anti-oxidation properties. They will not tarnish under 300℃ and can be used normally under 500℃ for a long time. They can resist corrosion caused by water and mud. Its ability to resist corrosion caused by water is better than that of hot dip aluminum galvanization, and its ability to resist corrosion caused by mud is better than that of hot-dip zinc galvanization. They are the ideal materials for auto mufflers, exhaust pipes, food dryers, water heaters, etc. In addition, its heat reflection ratio exceeds 75% and is twice as high as zinc galvanized steel sheets;

(3) Excellent properties for being coated and processed. They are highly adhesive to organic color coatings. Its processed and welded properties are similar to those of zinc galvanized steel sheets. They can be bent and pressed while maintaining exceptionally beautiful appearance. Since aluminum is lighter than zinc (the density of aluminum and zinc galvanization is 3.7kg/dm3 as compared with 7.1kg/dm3 for zinc galvanization), for galvanization of the same thickness, aluminum and zinc galvanization reduces the amount of metal used and hence results in cost savings.

6.Electric Steel

| Product introduction | 1.Hot rolled electric steel 2.Cold rolled non-oriented silicon-steel sheet 3.Cold rolled oriented silicon-steel sheet 4.Cold rolled high-magnetic-inductionoriented silicon-steel sheet |

|---|---|

| Application | 1.Hot rolled electric steel:Mainly be applied forminiatureelectricmotor,micromachine. 2.Cold rolled non-oriented silicon-steel sheet:mainly be applied for engine-building.Silican content is 0.5%-3.0%.The Bs contained in Cold rolled non-oriented silicon-steel higher than in oriented silicon steel;compared to hot rolled silicon steel,its has well-proportioned thickness,high-precision size,glazed and regular surface,thus raising block coefficient and magnetic fuction. 3.Cold rolled oriented silicon-steel sheet:mainly be applied for transformer production.Compare with cold rolled non-oriented silicon-steel sheet,oriented silicon-steel has strongdirectivity. 4.High-magnetic induction Cold rolled oriented silicon-steel sheet:they are single-tropism steel strip,mainly be applied for all type of transformer,choke,electromagnetic component in telecommunications and apparatus industry. |

| Silicon Steel grade | Non-oriented silicon steel strip:0.35mm35W270、35W360、35W440;0.50mm50W310、50W400、50W470、50W540、50W600、50W700、50W800、50W1000、50W1300;0.65mm65W600、65W700、65W800、65W1000、65W1300、65W1600; Oriented silicon steel strip:0.27mm27QG110、27QG120;0.30mm30Q120、30Q130;0.35mm35QG125、35QG135、35Q165 |

| Size | The general length for electric steel is 2000 meters. |

| According standard | Cold rolled grain orientation、non-oriented magnetic steel sheet:GB/T2521-96 Cold rolled magnetic steel sheet:Q/WG(GG)02-1998 Cold rolled grain orientation silicon steel thin strip:Q/WG(GG)04-1996 Tandem-cold-rolled non-oriented electric steel strip:Q/BQB480-2003 |

Mr Jack Yuan

Manager of Export Dept.

Fax: +86-21-56391811

Mobile:+86-15821118476

Mail: hkhy007@cnhuaye.com

Copyrights (C)2007-2025 Huaye Hongkong All rights reserved 沪ICP备17049918号-1